PRO-Tech Italia Impianti e macchinari per l’industria alimentare | linee di produzione pasta alimentare lunga ALFA - BETA - DELTA

Elevatori e trasportatori a tazze

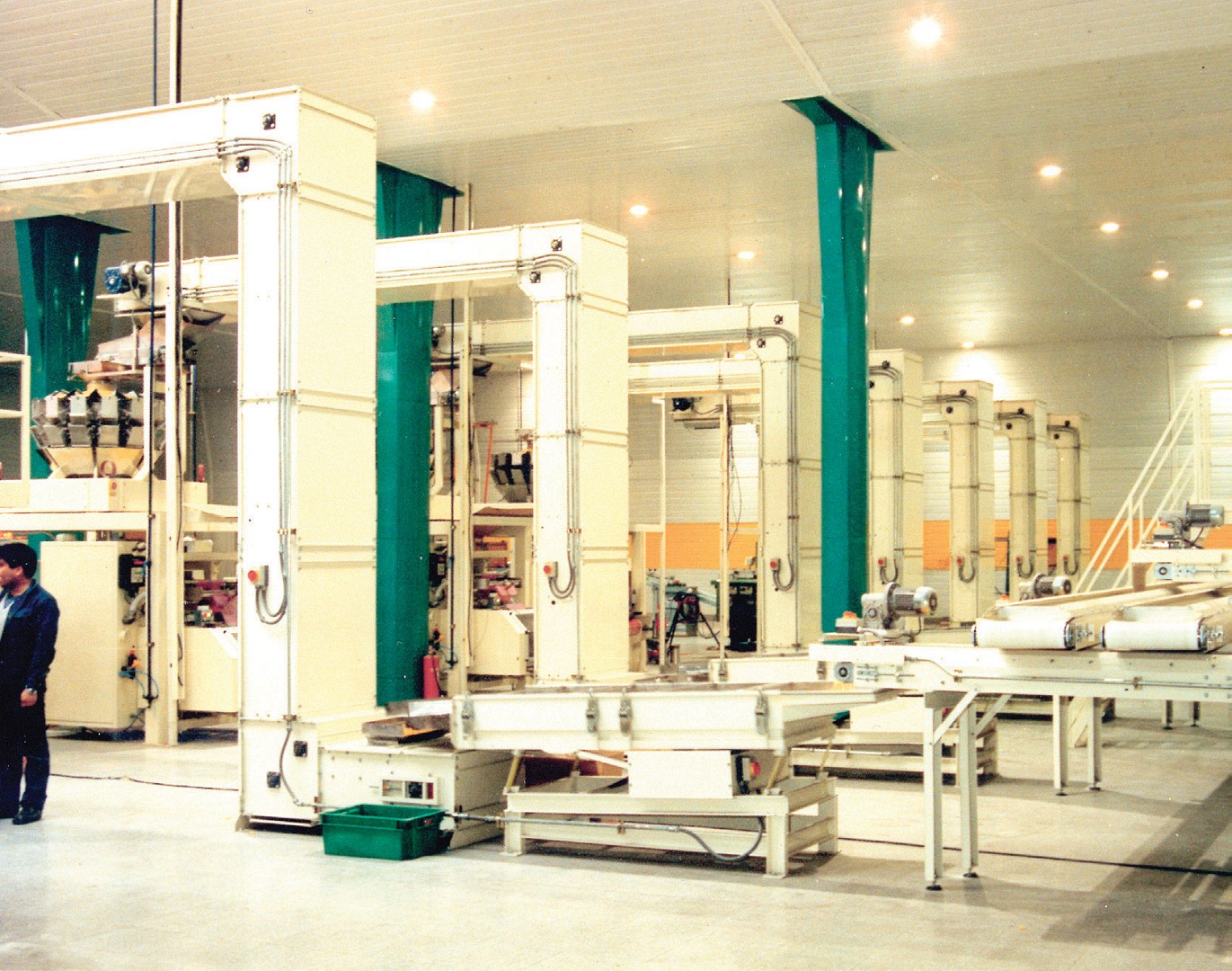

L’elevatore a tazze ALFA-1, soddisfa le molteplici esigenze di trasporto e sollevamento delle industrie alimentari, assicurando massimi livelli di efficienza ed igienicità.

L’elevata affidabilità, robustezza e semplicità di impiego dell’elevatore ALFA-1 ne fanno l’apparecchiatura ideale per l’installazione in linee di processo, caricamento di impianti di insilaggio, ed alimentazione di impianti di confezionamento.

Oltre alla serie ALFA-1, sono disponibili anche la versione BETA-1: trasportatore orizzontale a tazze e la versione DELTA-1 ad anello e forme complesse; con tutte queste versioni e grazie alla possibilità di combinarle tra loro non vi sono, praticamente, limiti alle possibilità di impiego di queste macchine.

La struttura portante è realizzata con elementi modulari imbullonati per ottenere una costruzione leggera ma nel contempo rigida e stabile che evita il ristagno di polveri all’interno della macchina.

Il sistema di trasporto si basa su due catene in acciaio di elevata resistenza pre-stirate in coppia per assicurare un perfetto allineamento delle tazze; il tipo di catene adottate garantisce lunga durata, funzionamento costante senza strappi e ridotto impiego di potenza.

Le catene scorrono su guide in materiale plastico autolubrificante inserite in astucci di alluminio; questo montaggio, stabile e sicuro con qualsiasi carico e velocità di traslazione, ricoprendo le catene assicura una elevata igienicità di trasporto in ogni condizione.

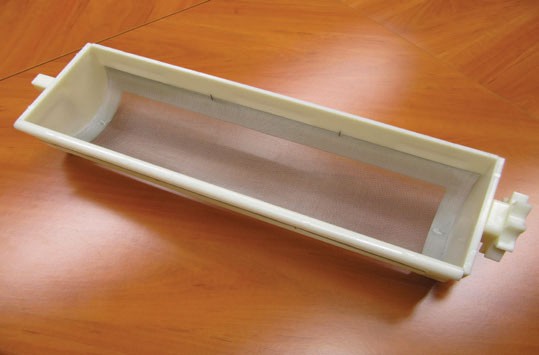

Le tazze di trasporto prodotto sono disponibili con larghezza 300; 500; 700 mm per le versioni realizzate in resina ABS alimentare, resina ABS alimentare e rete inox AISI 304 e resina ABS alimentare rilevabile al metal detector.

Le tazze sono disponibili anche in acciaio inox AISI 304 nelle larghezze: 300; 500; 700; 900; 1000 mm.

Il carico prodotto nelle tazze avviene senza nessuna perdita grazie alla completa sovrapposizione dei bordi delle tazze e grazie agli appositi pattini di tenuta, che chiudono perfettamente i fianchi della zona di carico.

La motorizzazione degli elevatori è dotata di frizione meccanica con sonda di controllo elettronica per la protezione contro i sovraccarichi.

Su ogni macchina possono essere installati numerosi punti di scarico, di tipo fisso o servo comandato, nei punti desiderati e grazie alla rotazione a 360° delle tazze lo scarico del prodotto è sempre totale anche con prodotti leggeri o poco scivolosi.