PRO-Tech Italia Engineering & machineries for food industry | semi automatic lines for short and long cut pasta VERTI - I

Stainless steel storage silos

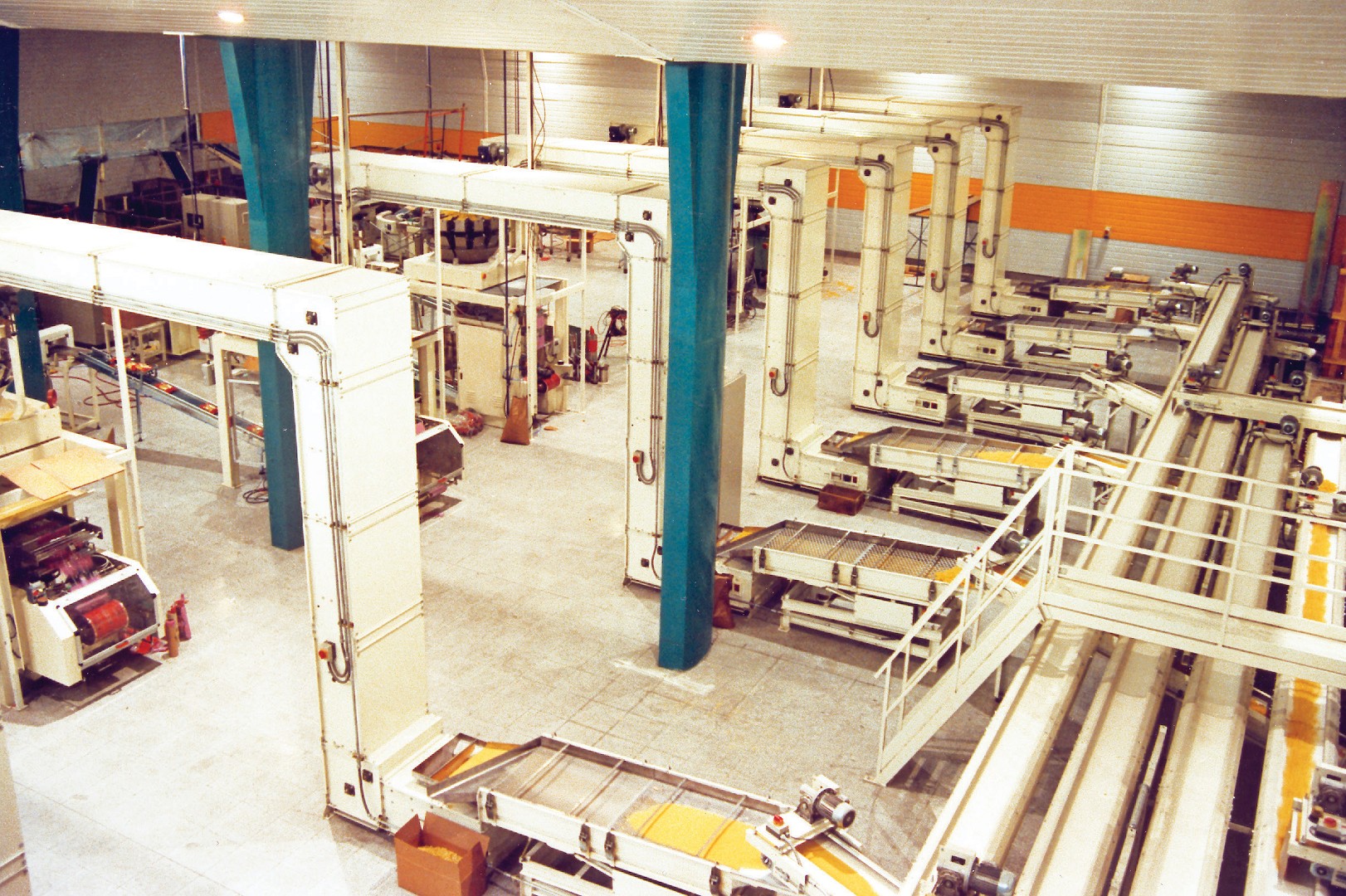

The storage plants made by PRO-TECH ITALY are the result of a long experience gained over the years and combine characteristics of extreme strength and solidity, maximum hygiene, ease of management, low maintenance.

The storage plants are suitable for storage of different food items in addition to the traditional short pasta, such as: special pasta (nouilles, capelli d’angelo (angel hair)), dried fruit, snacks, pellets, breakfast cereals, pet food, dried vegetables, couscous etc...

For products that are particularly difficult or extremely voluminous, it is available, on request, also a special version with horizontal planes featuring metal profiles.

For the storage of special or extremely abrasive products, such as couscous, stainless steel silos are available

- The silos of the VERTI-L series are made up of storage cells with one-piece plywood panels covered with

food grade extra-thick plastic laminate.

A significant feature of the one-piece panelling is the total absence of metallic profiles inside the silos, potential areas of stagnation of powder or product and source of possible contamination.

The external perimetral reinforcements of the cells make the silos extremely robust, avoiding swelling of the walls even in case of storage of extremely heavy products.

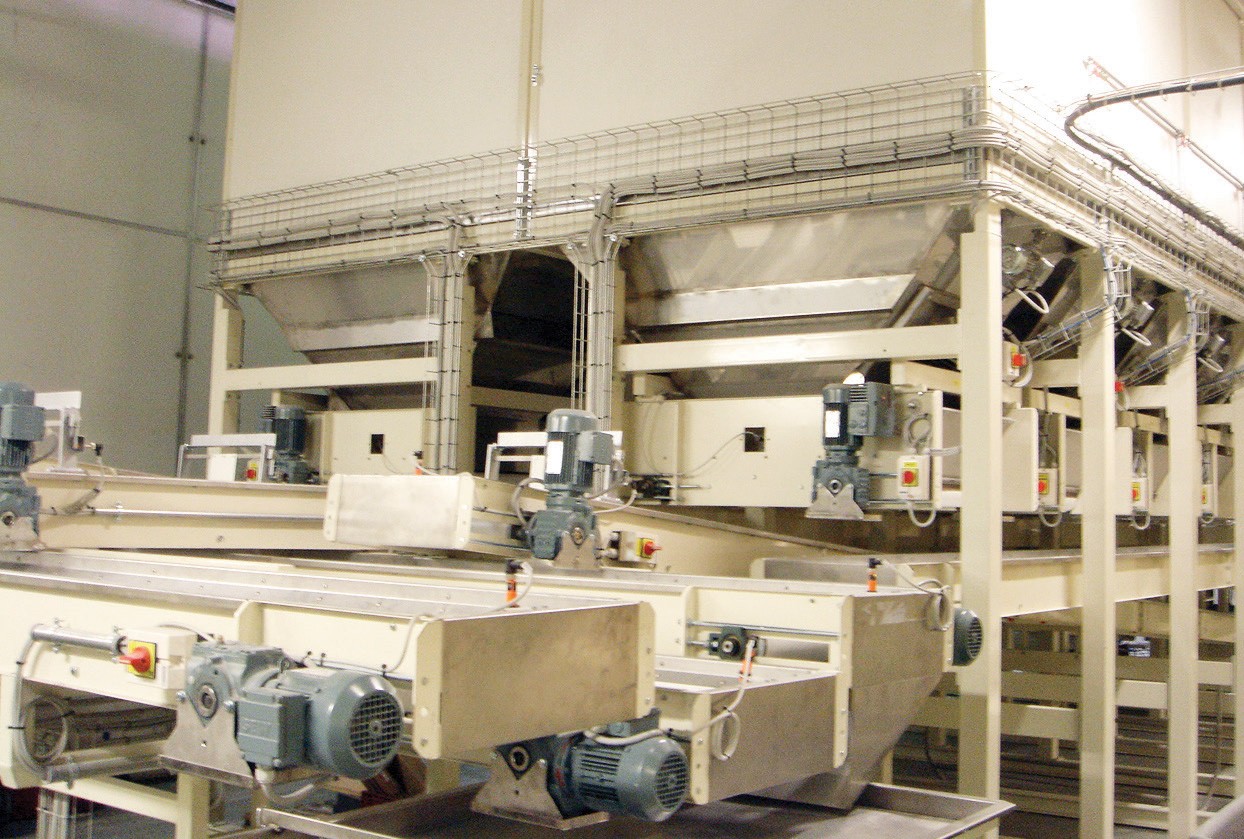

The hopper on the bottom of the silos, entirely made in AISI 304 stainless steel, guarantee extreme strength even in the presence of very high product loads, extreme hygiene of silos and durability of silos bottoms, not being subject to wear due to abrasion of the product. - The silos of the series VERTI-I are made with storage cells with bolted modular panels in AISI 304 stainless steel.

Stainless steel silos are suitable for the storage of abrasive products or products containing salt or sugar.

The reinforcements of the panels are positioned on the outside of the cells to prevent swelling, while inside the silos there are stainless steel tie rods.

The hoppers on the bottom of the silos, entirely made in AISI 304 stainless steel, guarantee extreme strength even in the presence of very high product loads, extreme hygiene of silos and durability of silos bottoms, not being subject to wear due to abrasion of the product.

loading system

The loading system of the silos of the series VERTI-L and VERTI-I uses bucket elevators or bucket conveyors provided with multiple outlets.

Bucket elevators and conveyors are equipped with transport buckets in different sizes, capable of carrying extremely high quantities of product.

The buckets may be in food grade ABS plastics, in ABS plastics with stainless wire mesh, in ABS plastics metal detectable by metal detectors or on request in stainless steel AISI 304.

On request it is also possible to realize loading systems with reversible belt conveyors, or with motorized conveyors.

To avoid product breakage inside the silos, spiral lowerators, made of stainless steel, suitably shaped to ensure high product capacity are provided.

Different types of spiral lowerators are available, based on the characteristics of the product.