PRO-Tech Italia Engineering & machineries for food industry | semi automatic lines for short and long cut pasta SB - 1

Cleaning sieves monolayer

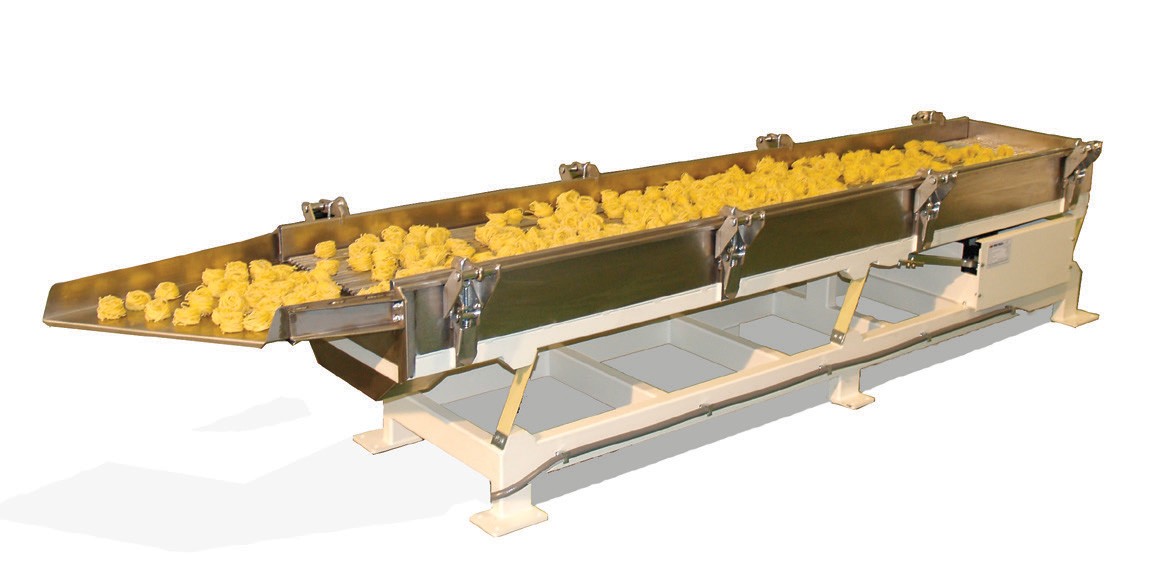

The sieves of the SB series are especially designed to meet the many cleanliness, separation, de-pulverisation and calibration requirements of food industries ensuring the highest effectiveness and hygiene levels.

The high attributes of the SB series sieves, as regards to reliability, strength and ease of use, make them the ideal equipment to be installed in process lines, silo plant loaders and feeders for cycle packaging systems.

Sturdy and reliable even with high loads and heavy duties, it is capable of guaranteeing very high flow rates with heavy or non-slippery products, with prevailing 24/24h operation.

The sieves of the SB series can be supplied with one or two sieving levels so as to meet any operational requirement

The constructional characteristics of the SB sieves allow using them for the selection and separation of a wide range of products, such as : dry short pasta, fresh pasta and stuffed, pasta nests, couscous, dried fruits, snacks, rice, corn-flakes, coffee in grains, animal feed, seeds, dried legumes and many more.

The load-bearing structure is made of sheet plates and high-thickness sections of carbon steel or stainless steel, obtaining a strong and sturdy structure designed to last for many years and to guarantee a perfect support for the sieving meshes.

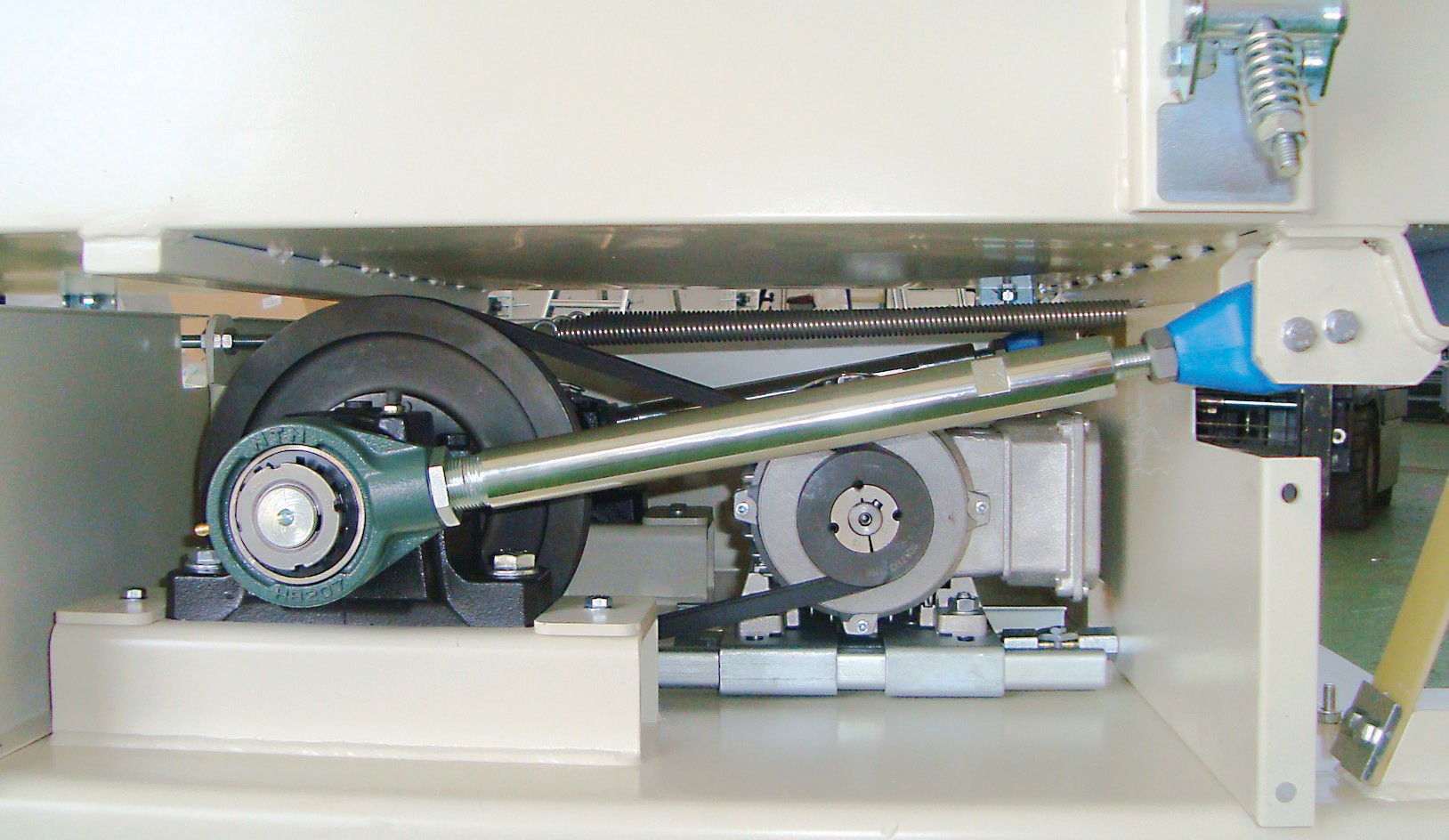

The sieving system is based on the oscillating uni-directional movement of the channel, which is driven by a camshaft and that forces the product in transit to make a continuous series of “micro-jumps”, pushing the product forward and favouring the separation of foreign bodies from the product; this system is undoubtedly the best in terms of effectiveness and results.

The core of the machine is the channel oscillation system: it is particularly strong, carefully built and reliable, and it can last for many years without stops; it consists of a camshaft made of special steel mounted on cast iron support with double crown ball bearings, steel rods, three-phase electric motor and beams of special synthetic material with high elastic response.

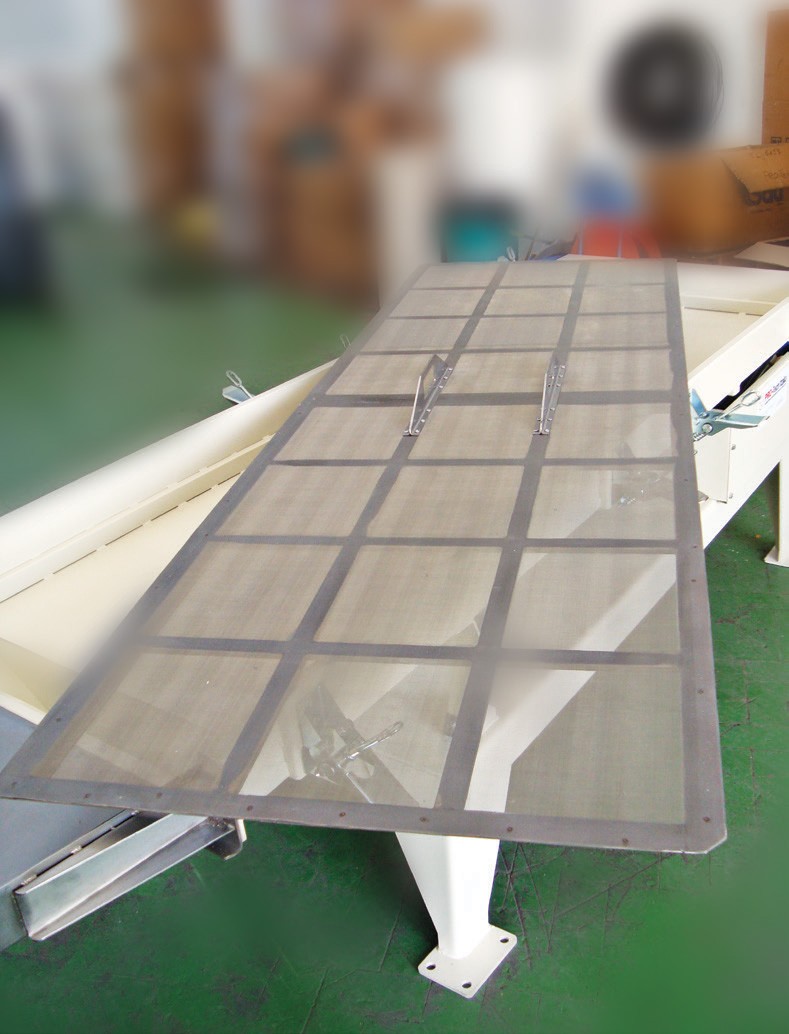

The sieving meshes, as well as any other part coming into contact with the product, are made of AISI 304 stainless steel; a wide range of versions and gauges are available, so as to meet every possible treatment requirement.

Mesh replacement is performed quickly, with no need for tools, thanks to the practical and strong locking system, consisting of steel levers fitted with compensation springs, which ensure perfect locking of the meshes with any operational speed, even after years and years of heavy-duty operation.